Working with JARE Industries

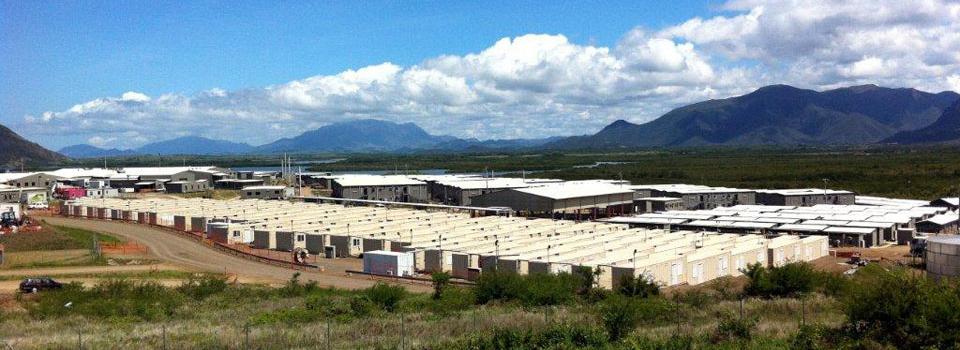

JARE INDUSTRIES is a sustainable modular, anti-seismic, anti-cyclonic, construction specialist.

We build:

- housing camps,

- showers and toilets modified containers,

- schools,

- standard housings,

- offices,

- workshops…

We operate worldwide:

- in Europe (UK, Denmark, France, Greece…),

- in Pacific area (New Caledonia, Australia, Vanuatu…),

- and in Africa (Ivory Coast...)

We have a very good knowledge of the use that will be made from our products under very hard long term using conditions (talking here as well as about the way human people are living or using with not much respect to the material in our houses, as well as transportation, hard weather condition, cyclonic and earthquake conditions that our modules are withstanding).

We are working with some of the major mining companies (Vale, Glencore, Eramet, BHPB….), on one of the world main industrial construction site, and with Engineers’ offices (SNC Lavalin, Technip, Hatch, Saipem….).

We have always followed very high standards requirements (France NF, CE, BS, USA, Australia…).

We have a high production and delivery capacity and have large scale project references.